When making and replenishing the drilling fluid, or changing the density and viscosity of the drilling fluid, we need to add drilling materials (such as bentonite, barite powder, etc.) and relevant additive to the mud circulating tank. Direct adding of these materials may cause depositing or caking so that the additive can not disperse finely. In order to avoid this, we need a special kind of mixing device.

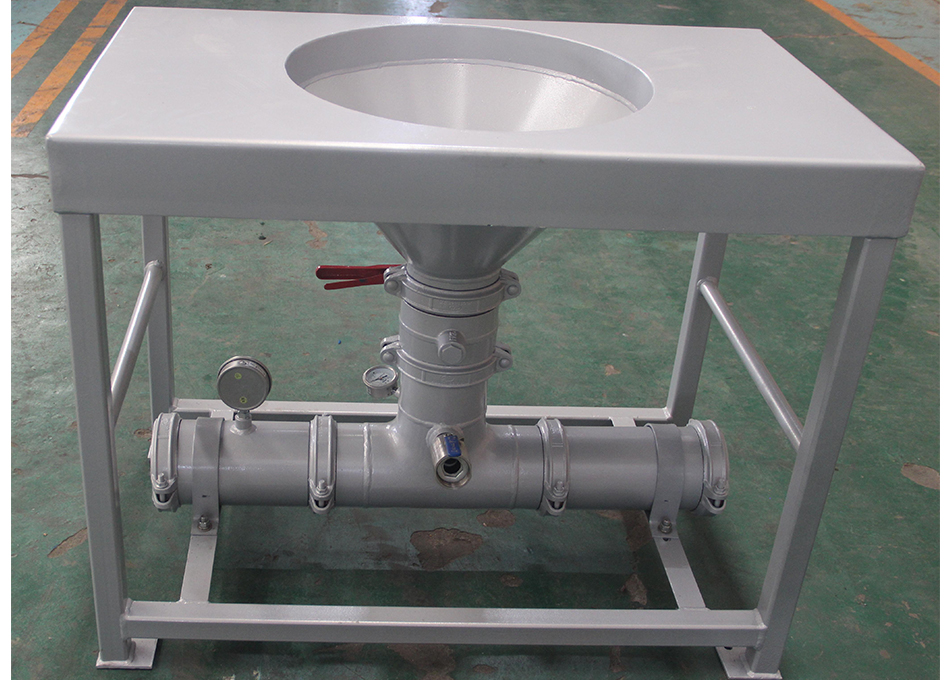

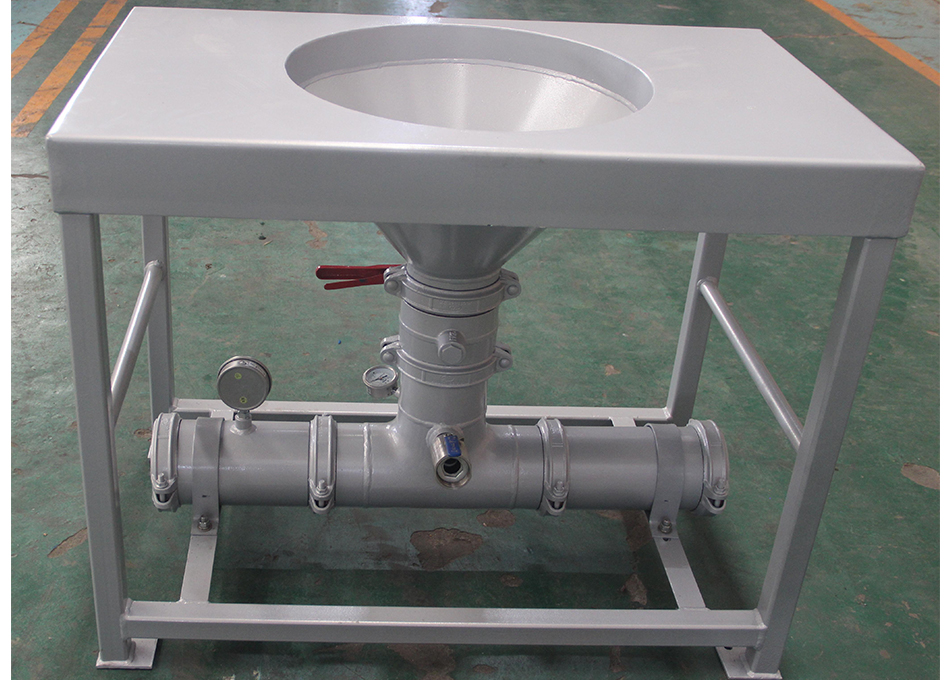

There are two types of common drilling fluid mixer. One is jet hopper HJM100/HJM200, and the other is vortex mixer HVM250.

HJM100/200 and HVM250 is designed with the following characteristics:

1. The new designed mixing chamber is helpful to make the bentonite well-distributed.

2. The unique design of the charging hopper and platform is easy for operation.

3. HJM100/200 makes use of Bernoulli Effect, which makes the outlet of the drilling fluid have pressure head.

4. HVM250 vortex mixer absorbs the charged materials to the inner chamber to achieve good mixing effect.

5. The compact structure is space saving.

| Model | HVM-250 | HJM-200 |

| Capacity(m³h) | 260~300 | 200 |

| Inlet pressure(Mpa) | 0.3~0.6 | 0.3~0.6 |

| Outlet pressure(Mpa) | ≤0.04 | 0.1~0.2 |

| Nozzle size | / | 2" |

| Inlet | 6" | 6” |

| Outlet | 6" | 6" |

| Weight(kg | 480 | 120 |

| Dimensions(mm) | 1500×700×1090 | 1370×750×970 |

Please feel free to contact us. We will get back to you ASAP.